VITREOUS ENAMEL

We manufactured and distributed FACADES building enclosure materials.

Expert in producing Vitreous Enamel products.

WHAT IS VITREOUS ENAMEL?

Vitreous Enamel (VE) is a composite material made by fusing inorganic glass material with a substrate. Modern VE panels combine enamel with low carbon steel and additional backing materials such as calcium silicate and aluminium honeycomb. These materials combined results in many strengths and advantages, including resistances to fire, chemicals, wear, and ultraviolet light. In addition to its strong physical qualities, it also has a smooth non-porous surface that is easy to clean.

There are many advantages to using Vitreous Enamel. It is a cost-effective material, suitable for many environments and projects because of its durability, ease of installation and maintenance and versatile aesthetic options.

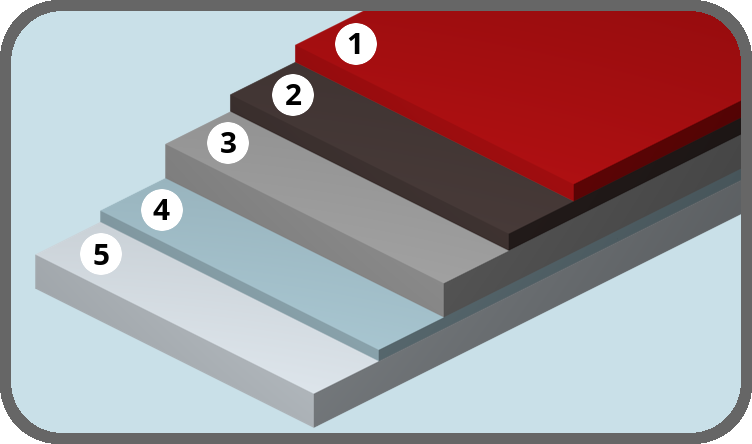

COMPOSITION OF

VITREOUS ENAMEL

1. Top VE Coat

2. Ground VE Coat

3. Low Carbon-content Steel Sheet

4. Adhesive

5. Backing Material

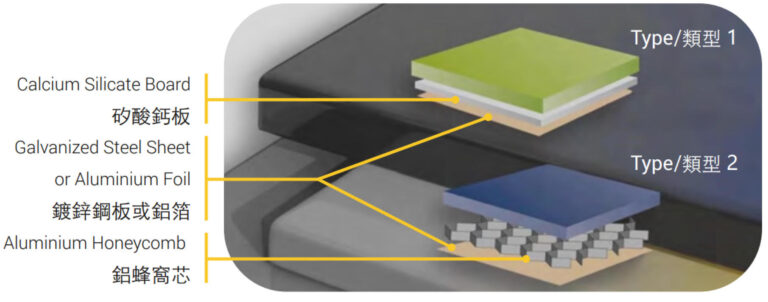

VE BACKING

Additional layers are bonded to the back of the panel to improve strength and resistance properties.

There are 2 types of backing used in our VE Panels; choose between Calcium Silicate Board or Aluminium Honeycomb for the middle layer, and coverd in Galvanized Steel Sheet or Aluminium Foil.

WEATHER RESISTANCE

Enamel products are able to maintain its surface glossiness and colour despite long-term exposure to air pollution, humidity, strong winds, extreme weather temperatures and acid rain conditions. It has high weatherability, and an expected lifespan of 30 years.

EASY CLEANING

Vitreous enamel is non-porous with a smooth surface. Together with its chemical resistance and non-stick properties, this allows for all sorts of substances to be cleaned off easily, including graffiti, without worrying about colour-fade or damage by detergents. It is also naturally resistant to mould or mildew.

WEAR RESISTANCE

The panels are very resistant to scratching with Mohs hardness between 6-7. There is no need to worry about scratches or chipping when performing industrial cleaning.

UV RESISTANCE (COLOURFASTNESS)

Vitreous enamel is unaffected by ultraviolet light, so it can retain its original colour and lustre for decades even under continuous sunlight.

FIRE RESISTANCE

Enamel plate is non-combustible and can resist temperatures up to 400°C without suffering permanent damage, even if cooled rapidly to room temperature within 30 seconds.

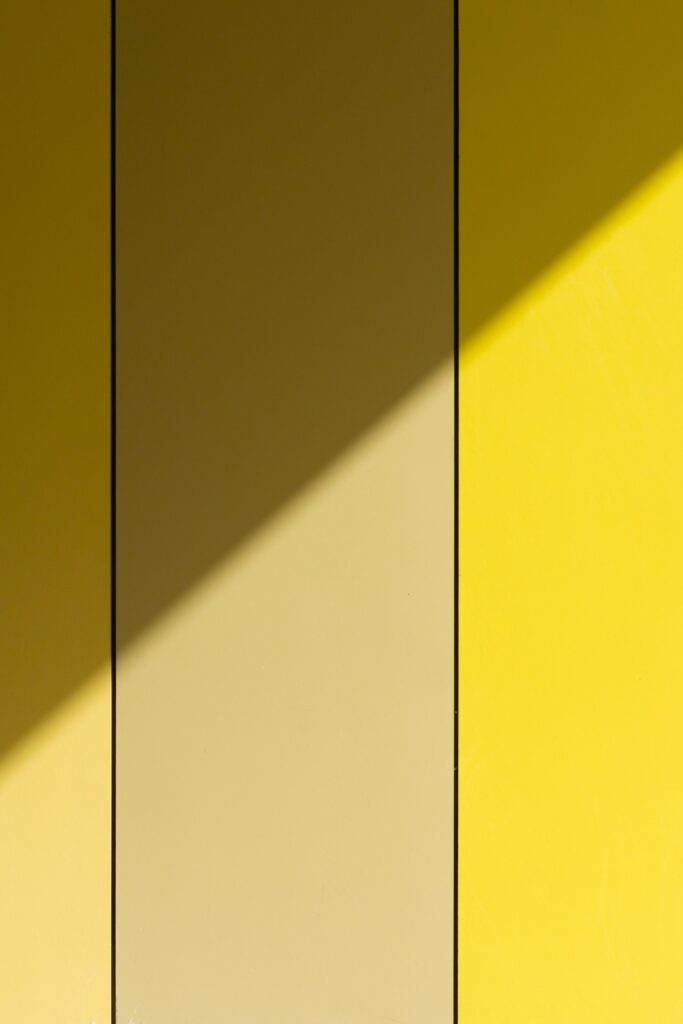

AESTHETICS

A variety of looks and colours can be printed onto to the panels, allowing for all sorts of creative designs and applications. The range of colours available are virtually limitless.

CHEMICAL RESISTANCE

Vitreous enamel is highly resistant to corrosion from all sorts of chemicals, including organic solvents, acids, alkalis or salts.

FLEXIBILITY

Enamel Panels can be precisely designed and accurately produced for many types of structures and shapes, ensuring a predictable and reliable installation without the need for in-place bending or forced fit.

APPLICATIONS OF VE

Infrastructure Applications

Vitreous Enamel Panels have applications for all kinds of construction and urban development projects.

Using VE panels will be appreciated by construction companies and property owners/management as a cost-effective and low maintenance material, and also by designers for its design flexibility and potential.

VE Panels can be easily produced to have a uniform style and decoration if desired, making it a good fit for locations such as retail stores, branch offices and transport hubs to maintain a consistent look across large enterprises or organisations.

Tunnel Cladding

High durability and low maintenance costs make VE panels highly suited to tunnel or other road works. They are a fire safe material suitable for confined environments with strict safety requirements.

They can also be manufactured with a high glossy finish suitable for low-light environments; this allows for saving electricity on less powerful lighting while still being adequately illuminated.

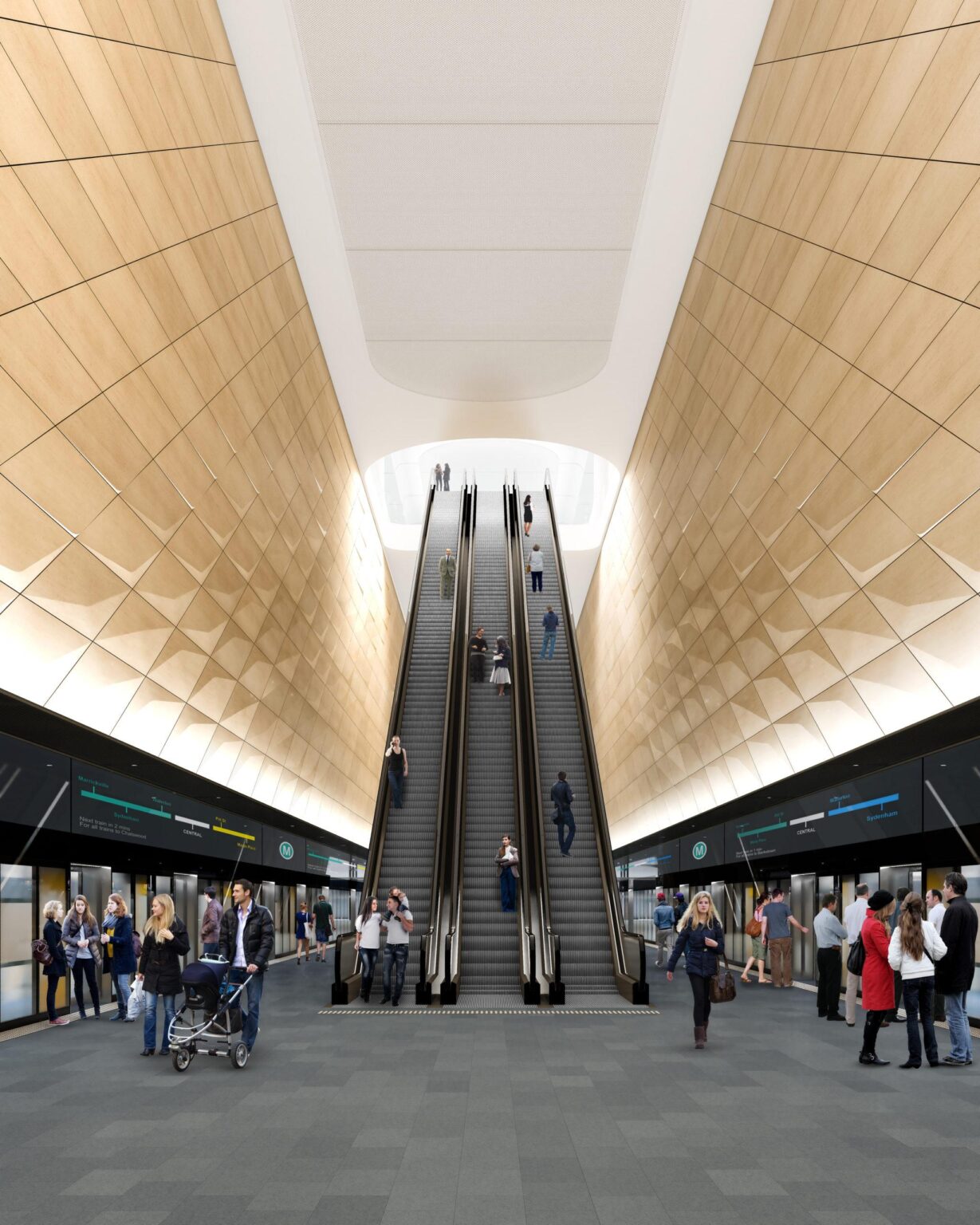

Subway Stations

For Subway Stations, perhaps the most valuable property of our VE panels is its easy maintainability. Resistance to physical damage, colour fade and graffiti, as well as its smooth easy-to-clean surface, makes VE panels particularly well suited to public transport stations.

VE panels can not only preserve a clean image, but with some creative design, they can add a splash of life into a bustling, stressful environment.

It is increasingly becoming the standard of subway stations across the world.

Sydney Central Station – Australia

Sydney Central Station – Australia

The location of the metro platforms at Central will facilitate a critical interchange, fully connecting the station with suburban, intercity and regional rail services, buses, coaches and light rail.

Architectural Applications

It is a growing trend to use VE panels to decorate buildings for a clean and modern look. The versatility of the panels means that they can be custom made to suit a variety of projects.

The possibilities are endless with the colours ranging from humble earth tones to spectacular vibrancy; or with printed patterns and designs that allow for much more creativity.

Its weather and colour fade resistance allows the building to retain its original look throughout the building’s lifespan, with minimal maintenance required.

VE panels can have their own uniquely modern and sleek look, but they can also be a cost-effective alternative to other materials such as stone

tiles.

Stone patterns can be permanently printed onto the panels so that they can mimic the aesthetic of other materials, while still have all the benefits of being Vitreous Enamel.

You can use as much or as little in your designs, whether it is to cover the entire external wall, or to decorate the internal lobby, or to cover building columns.

Such is the versatility of this product in your designs. Our designers can assist architects in understanding the versatility of VE to achieve or surpass their artistic vision.

Public Amenities

Produced in various shapes, colors and sizes and manufactured to customers’ specifications with a comprehensive installation system, vitreous enamel offers great versatility for public amenities such as kiosks, phone booths, bus-stops, park benches, street signage, landmarks or art pieces.

Not only are they presented in brilliant colors, they are also able to carry permanent multi-color graphics of complex design for environment or theme enhancement.

VE provides unlimited possibilities for Designer, Landscape Architect, Architect and Artist to realize their ideas.

Its durable coating protects itself against vandalism by commuters and outdoor weather conditions under strong sunlight, raining, damp environment or on the coast.

MANUFACTURING & FABRICATION

We are well-equipped to provide a comprehensive service for the DESIGN, FABRICATION, SUPPLY and INSTALLATION of Vitreous Enamel (VE) Panels.